Summary:

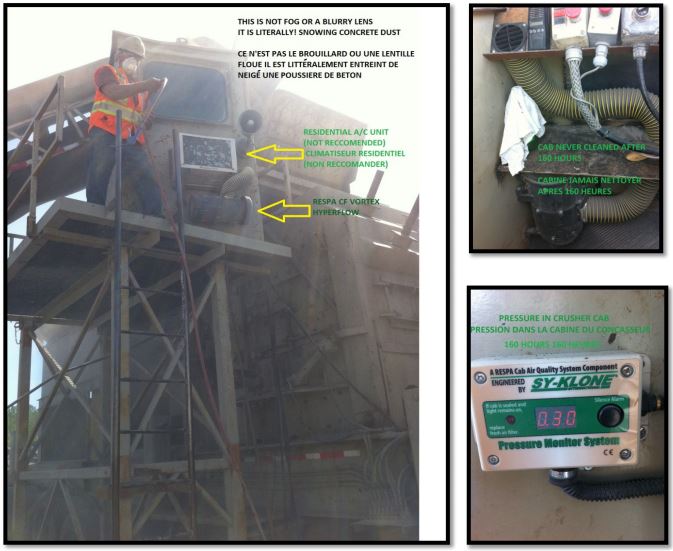

RESPA®-CF Fresh Air system with Electronic Pressure Monitor and RESPA®-CFX Recirculated Air system were installed. Our current products, RESPA-CF2 and CFX2, are based on the same technology but are more rugged with additional filter options. Results after 1,120 hours: no HVAC breakdowns or clean outs, air quality dramatically improved. The operator was very happy with the improved air quality in the cab. High Respirable dust concentrations in crusher cabin require the HVAC evaporator core to be cleaned weekly. Often the air quality in the cabin is highly contaminated with rock dust, reducing operator comfort as well as the life of the machine.

High Respirable dust concentrations in crusher cabin require the HVAC evaporator core to be cleaned weekly. Often the air quality in the cabin is highly contaminated with rock dust, reducing operator comfort as well as the life of the machine.

“Previously, we had to scrape off concrete from the evaporator. The HVAC unit would never have made it past one season. The HVAC unit is a residential-type unit and not made for this environment. Now that we have installed the RESPA System, the HVAC system is ready for the next season. Also, air quality in the cab is great. I did not expect the system to give this level of performance. The system has done an amazing job of keeping the dirt out of the cab. I am very satisfied and will recommend this system for our other three mobile crushers.”

–Manager’s comment

Read the case study:

Quebec Crusher Cab Case Study[PDF]