Home » VORTEX® Engine Precleaners » XLR Powered Precleaner

XLR Powered Precleaner for Engines

(XLR = eXtra Low Restriction)

The XLR Powered Precleaner® offers maximum precleaning in demanding environments with the lowest possible restriction to protect your engine! This high efficiency powered precleaner removes 99.99% of ISO fine test dust. With the addition of power, there is zero restriction up to 130 CFM (3.68 m3/min).

- High efficiency powered precleaner removes more than 90+% of the dust BEFORE it reaches the prefilter.

- High efficiency radial seal prefilter then removes 99.99% of ISO fine test dust.

- Patented self-cleaning prefilter drops dirt continuously, which is then ejected from the XLR filter housing.

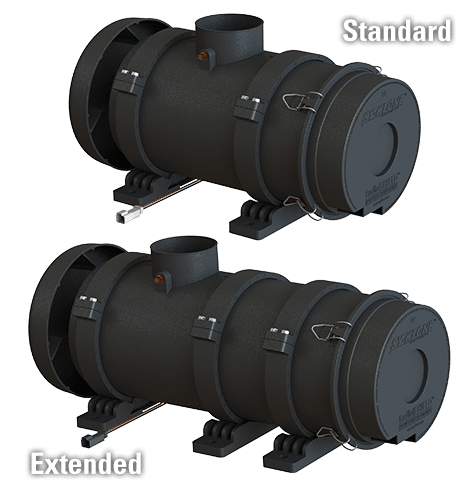

The XLR Powered Precleaner offers two sizes to maximize your precleaning ability. The unique design allows for an easy air filter change with no engine contamination.

Benefits:

- Most effective “impossible dust environment” engine precleaner ever invented

- Lowers cost per operating hour

- Quickly recover cost of investment

- Extends primary engine air filter life for an indefinite period of time

- XLR prefilter changes do not expose engine to field service contamination

- Improved oil samples (significantly lower contaminate levels)

- Helps to preserve your engine, catalytic converter, and prevents related downtime costs

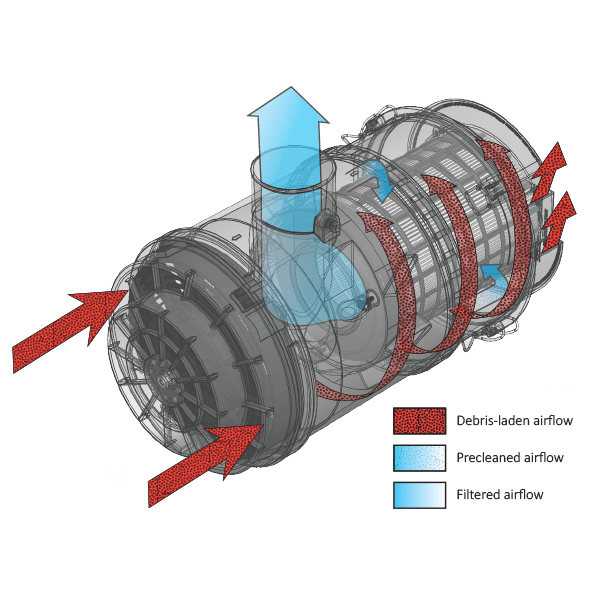

How it Works:

- Debris-laden air enters the precleaner.

- The motor whips the air into a vortex with the debris riding along the outer walls.

- Debris is ejected from the precleaner.

- The clean air in the center of the system is then pushed through the filter with very low restriction.

- The filter and housing are self-cleaning as debris falls off the filter and is then ejected from the housing.

Specifications:

Air Flow Range:

Covers engine air flows up to 350 CFM (9.91 m3/min) and much higher with multiple unit installations; contact Sy-Klone for assistance.

Mounting:

The XLR can be mounted horizontally or vertically (with rain cap end up).

Optional Flange Mount (RIC0701) available.

Precleaner Maintenance:

Patented self-cleaning filter drops dirt continuously, which is then ejected from the filter housing.

Recommended Uses:

Extreme environments including Agriculture, Waste, Mining, Construction and Forestry, or anyplace where restriction is a problem.

Elevation:

Sea Level to 10,000 feet

Precleaning Efficiency:

99.99% Efficient on ISO Fine Test Dust.

Operating Range:

0-350 CFM (9.91 m3/min)

Operation temperature:

-40° F to +176° F (-40° C to +80° C) continuous; +185° F (+85° C) short exposure

Construction:

Glass-filled injection molded polypropylene exterior, steel hardware, aluminum fan blade, 12v and 24V DC motor with sealed housing and sealed ball bearings. 288W initial start-up, 144W constant.

Not for use in explosion-prone environments.

What's the air flow range?

Covers engine air flows up to 350 CFM (9.91 m3/min) and much higher with multiple unit installations

What is the operating airflow range?

0-350 CFM (9.91 m3/min)

How will I know when I need multiple XLRs?

Each unit covers an engine airflow up to 350cfm. Anything higher than 350 cfm will require additional units.

What are the voltage options?

Available in 12 and 24 volts

How much restriction is added?

There is zero restriction up to 130 cfm.

Is there an operating temperature range?

-40° F to +176° F (-40° C to +80° C) continuous; +185° F (+85° C) short exposure

Does XLR replace my engine filter?

No, the XLR is an engine prefilter that offers precleaning prior to the primary filter (outer filter).

Is my safety filter necessary?

Customer Preference. With the XLR’s high efficiency filter and radial seal, debris should not pass the prefilter and the primary filter becomes the safety filter.

After installing XLR, my original primary filter is getting dirty. Why?

There is a leak in the system somewhere after the XLR.

Can my XLR be mounted vertically or horizontally?

The XLR can be mounted horizontally or vertically (with rain cap end up). Optional Flange Mount (RIC0701) available for through-the-wall installations.

Are all of the installation parts included?

No. Installation varies from machine to machine. Sy-Klone offers various kits to support installation on a variety of machines. Sy-Klone also offers drawings for multiple installation adaptation for your use.

Is there a specific kit for my vehicle?

Sometimes. Call Sy-Klone for more information. We also offer generic installation kits.

How does the XLR Powered Precleaner compare to other precleaning technologies?

XLR maximizes precleaner efficiency across the entire engine airflow range, as well as incorporates a high efficiency prefilter. It is a fantastic solution for extreme environments.

Does installing an XLR void my warranty?

No. XLR is a precleaner. The original machine configuration remains the same.

How much more efficient are the XLR prefilters compared to typical engine filters?

Much more efficient! Typical engine air filters arrest particulate down to 10 microns. XLR high efficiency filters arrest particulate down to 0.3 micron.

How is XLR able to provide such low restriction precleaning?

Instead of using the power of the engine to draw air through the precleaner, the precleaner uses its own motor and fan to push air through the precleaner, thus reducing restriction.

How far away from the engine air intake can I install an XLR?

The farther away, the more restriction.

Why is my XLR not working?

+ Check connectors

+ Check power to XLR and relay

My vehicle restriction (change filter) indicator issued a warning. What do I do?

+ Check XLR prefilters for debris.

+ If dirty, change.

+ If not dirty, check for XLR operation

+ At air cleaner outlet tap point, verify restriction reading with handheld manometer. Compare to Vehicle reading.

Can I blow out my XLR filters?

No. Blowing out filters can damage the high efficiency filter media.

Does engine series (Tier 3, Tier 4, etc.) affect my ability to use XLR?

No. XLR can be used on all engines.

What inlet options are available?

Rain cap is standard. Heavy debris screen (RIC0918) is recommended for Landfill and other heavy-duty applications.

Downloads

Resources Available

- Assembly Diagrams

- Multiple-Unit Plenum Diagrams

- Installation Guides

- Service Parts Guides

- Filter Change Instructions