Benefits of Incorporating ISO 23875 into your Occupational Health and Safety Management System

The ISO 23875 cab air quality standard was developed for the extreme conditions of mining but can be used in any industry to protect heavy-equipment machine operators from harmful respirable particulate. It has been adopted as a national standard in many countries, such as in AS/NZS ISO 23875 Australia and New Zealand. So why implement ISO 23875 with Amendment 1 if it is not mandated by a regulatory body?

- The standard provides a holistic method to ensure good air quality for machine operators, regardless of the governing body. Using ISO 23875:2021/Amd.1:2022 as a methodology to maintain cab or enclosure air quality ensures that you have documentation showing air quality levels and what you are doing to control worker exposure when the OSHA or MSHA inspector arrives. ISO 23875 is an international standard that takes the mystery out of “how to consistently provide good air quality” to machine operators. From OEM design to machine-tender language when purchasing, retrofitting in the aftermarket, and lifecycle testing, implementing ISO 23875 means you can achieve exposure levels below permissible limits.

- ISO 23875 differs from most standards as it is not based on implementing a specific technology but rather on achieving a specified level of cab air quality. The standard provides a method for periodic air quality testing throughout the machine’s lifecycle to ensure the operator remains protected. This gives a company data its industrial hygienists can use to continually analyze and improve the air quality inside the cabs of its heavy machinery. Between tests, in-cab monitors ensure the operator is alerted when the cab loses positive pressure, meaning harmful dust can be sucked into the cab instead of clean air leaking out. The ISO 23875:2021/Amd.1 online training class from the International Society of Environmental Enclosure Engineers (ISEEE) teaches how to design, retrofit, performance test, certify, or maintain an operator enclosure. It provides practical examples and templates for the testing, reporting, and maintenance manual requirements found in ISO 23875:2021 with Amendment 1.

- It’s the right thing to do. Many heavy-machinery operators in mining and other industries are impacted by dust diseases without a cure. Silicosis, black lung disease, COPD, lung cancer, mesothelioma, and more can be caused by long-term inhalation of dust particles so small you can’t see them; too small for human lungs to expel by coughing. When an operator becomes disabled by dust-related lung disease, it affects more than the operator and his or her loss of income. Frequently, a spouse or other family member becomes a full-time caregiver, reducing income further, which can cause entire families to fall into poverty. On the other hand, implementing ISO 23875 can demonstrate corporate concern for their employees’ quality of life and assist in attracting and retaining a motivated workforce. Regulations tend to focus on specific particulate types, such as silica. The methods outlined in ISO 23875 are effective on all particulate types. Regardless of what type of particulate is causing health issues, whether coal dust, asbestos, beryllium, or silica, ISO 23875 provides a roadmap for achieving compliant air quality in machine cabs or enclosures.

- Those same dust diseases frequently cause workman’s compensation claims and lawsuits, including class-action lawsuits, which can impact a company’s financial health. Implementing ISO 23875 helps ensure that you have data showing what was done to protect your machine operators and the precise air quality in the cab at specified intervals. In South Africa, the Catholic Church, at the request of coal miners in its parishes affected by incurable coal workers’ pneumoconiosis (a.k.a. black lung disease), has organized a class-action lawsuit seeking compensation for those who worked for major mining companies since 1965 and were affected by coal-dust induced lung diseases and for their dependents. A previous settlement against gold-mining companies established a nearly 353-million-dollar fund for miners affected by silicosis and their families. ISO 23875 is an international best practice. Adopting the standard provides a powerful defense to mining companies seeking to protect themselves from potential liability.

- ISO 23875 includes the management of carbon dioxide levels in the cab. As the operator breathes in a small enclosed space, CO2 can build up very quickly, leading to fatigue and headache at lower levels and sleep at higher levels. Accidents and subsequent investigations can slow or halt operations depending on the severity. Given the size and power of the machines, an alert operator is extremely important for the safety of the operator, the machine, other workers, and potentially the job site.

In conclusion, implementing ISO 23875 is a win-win for all mining stakeholders, from machine operators to investors.

Next Steps

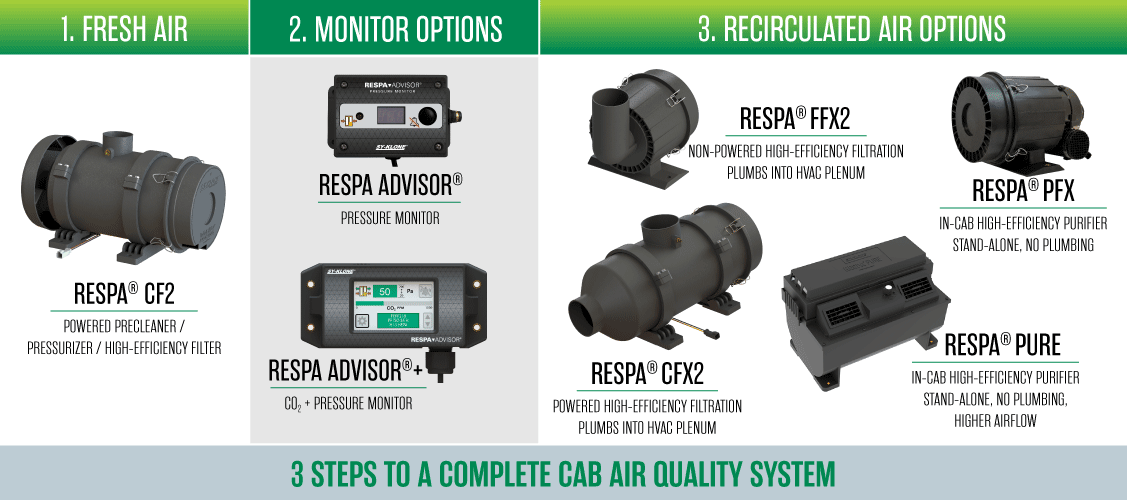

Sy-Klone’s 3-part RESPA Cab Air Quality Systems provide all the engineering controls needed for ISO 23875 compliance, ensuring compliant air quality in the cab regardless of particulate type, with high-efficiency EPA or HEPA level filtration. See our Where To Buy to find a dealer near you, or contact Sy-Klone with any questions. Meet exposure regulations with RESPA.