The Mining Safety and Health Administration (MSHA) has proposed reducing the allowable amount of silica dust and other harmful respirable particulate to which miners are exposed. The period for comments ended on September 11,2023, and we anticipate some form of the new ruling going into effect within a year.

In years past, the Occupational Safety and Health Administration (OSHA) which regulates other industries reduced the permissible exposure limit (PEL) from 100 micrograms to 50 micrograms, with an actionable level of 25 micrograms per cubic meter of air, calculated as an 8-hour time-weighted average (TWA). The changes MSHA is proposing bring allowable mining exposures to the same levels.

-

- MSHA Respirable Crystalline Silica Rulemaking Overview, with links to documentation, comments, etc.

- MSHA Fact Sheet [PDF]: Proposed Rule – Lowering Miners’ Exposure to Respirable Crystalline Silica and Improving Respiratory Protection

The MSHA changes are critical, as there are no cures for the illnesses caused by long-term exposure to respirable crystalline silica (RCS) and other particulate. “Each of these illnesses is chronic, irreversible, and potentially disabling or fatal,” as stated in the MSHA Fact Sheet. They include:

-

- RCS exposure-related diseases

- Silicosis

- COPD

- Lung cancer

- Kidney disease

- Emphysema

- Chronic bronchitis

- Coal Dust containing RCS exposure-related diseases

- Coal workers pneumoconiosis (black lung disease)

- Progressive massive fibrosis

- Multi-dust pneumoconiosis

- RCS exposure-related diseases

Sy-Klone applauds this action. Many countries now limit allowable exposure to 25 micrograms and have embraced the new global mining cab air quality standard, ISO 23875, which provides a methodology for how to achieve, maintain, and verify these levels on new and existing equipment throughout its lifecycle.

Sy-Kone’s area of interest is in protecting heavy equipment machine operators, such as miners in excavators and haul trucks, from overexposure to any kind of respirable dust, including RCS and coal dust, with RESPA cab air quality systems. This applies equally to those working in small enclosures, such as mobile control rooms, crusher cabs, and more.

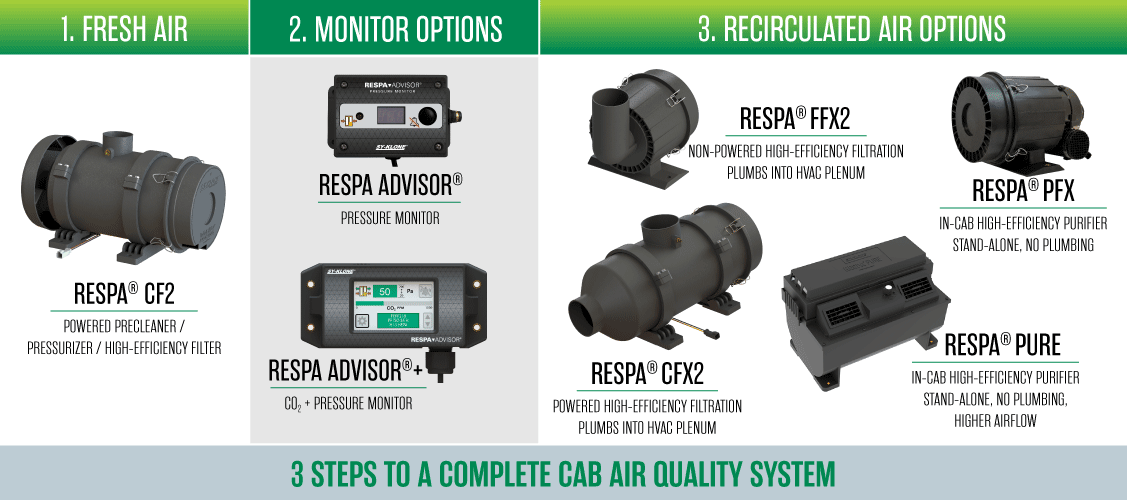

When you consider the mine site as a whole, the enclosed heavy machine cab is one of the most cost-effective areas to provide clean, safe air. With Sy-Klone’s three-part system, which includes fresh air precleaning/filtration/pressurization, recirculated air high-efficiency filtration, and real-time cab monitoring to ensure pressure and CO2 levels are safe, has been proven on mine sites all over the world. Sy-Klone has worked with some of the largest mining and aggregate companies to create a comprehensive air quality program for their machine fleets.

Installing a RESPA cab air quality system has many other benefits .

-

- Focusing on air quality shows concern for employees’ quality of life and can help attract and maintain the work force.

- The financial impact of medical payouts for death and disability due to respiratory diseases will be reduced over time.

- Providing precleaned air to the cab’s HVAC system helps avoid costly breakdowns from clogged evaporator cores and other failures, leading to longer HVAC life and less downtime due to failed systems.

- Clean air in the cab helps preserve the life of electronic equipment.

- Operator comfort and satisfaction substantially increase.

- RESPA also ensures adequate fresh air is continuously diluting CO2 build-up, increasing operator alertness.

Learn more about RESPA and its role in mining.

Learn more about the effects of CO2 build up on operators.